Laptops and Looms

I’m still mainly in London, waiting for various bureaucrats to process/stamp various documents, but for the tail end of last week found myself in an old mill near Derby, at Laptops and Looms.

Held in the world’s first water-powered cotton mill, Arkwright’s Cromford Mill, this meeting of thirty or so people was billed as a “small get-together to talk about the world of Making, how it might intersect with the Internet of Things and what implications that might have for Futures of Manufacturing and all manner of related things”. What follow are some scattered initial thoughts: not necessarily fully processed, but squeezed out of my head while they are still fresh.

Mornings consisted of talks — from the importance of craft, materials, and using your hands (Matt Cottam) to the bigger picture of history, economics, and politics (Dan Hill), to specific examples of people trying some of these things out as a business model (Alice Taylor/Makielab) – interspersed with open discussions. These were balanced by trips and tours to reminders and remainders of the region’s rich engineering, industrial, and manufacturing heritage. There was even a game of football and a bit of cricket (to give that proper feeling of a school trip).

I found the event interesting on a couple of different levels: as a designer who makes things, and relating to Urbanscale as a company, trying to get things made. And finally, on a more abstract level, it sparked off thoughts about what making and manufacturing, and the spaces and facilities that make or made this possible, mean for cities, countries, and regions.

As somebody who originally studied industrial design, and still occasionally draws on those skills, there were discussions of craft, making, and materiality that resonated deeply with me. And yet, I felt that there was an occasional confusion between “making” for its own sake (often described with a sneer as “craft”, or a hobby – itself a tangential discussion), as a prototyping process, as small-scale batch manufacturing, and mass manufacture, which are each completely different things. Different both in terms of the skills and an experience an individual should have to do them successfully, and what infrastructures and “dark matter” – politics, economics, culture – need aligning to make them possible, or easy, or more commonplace on the scale of a country or an economy. There are specific terms in there that need unpacking (as Matt Ward pointed out, in his talk on Terms and Conditions), and blending them all into one discussion practically guarantees confusion at some point.

An interesting sidenote to these discussions that I find worth mentioning was that the majority of people in the room came from “digital” backgrounds – with all the differences that implies regarding approaches, experience, and expectations. I always find the discussion of “the democratization of making” rather fascinating – what could be more democratized and accessible than wood, a hacksaw, a hammer and some nails? It would perhaps be more accurate to describe the possibilities of making to be increasingly overlapping with the digital domain – controllable from a computer (3D printing, laser cutting), linked to the open-source world (MakerBot), and increasingly programmable and scriptable. None of these things are easy or unskilled, but perhaps the skills required are closer to those individuals discussing them in this context (and often, online).

But other discussions also struck a cord, from the perspective of working for a small company interested in creating things that go out into the world, at scale – whether as part of street furniture (eg Urbanflow), or something like Project PERRY – and what it means to be a company of 4 or 5 people, versus the resources and economies of scale (but also, increased friction) of being somebody like Microsoft, Nokia, or Rolls Royce: the traditional model of “industry”. And this is where it got really interesting for me: discussions about the ability to have bits of projects 3d printed without having to own a 3d printer; of being able to develop and prototype electronics at a cost several orders of magnitude below what any of the above companies might spend on an R&D projects. We will never manufacture PERRY ourselves – for better or worse, that’s likely to happen in a factory on the other side of the world – but being able to leverage prototyping platforms (both electronic and physical) allow us to act in a way only bigger beasts would have been able to in the past. Big beasts that in terms of the economic, industrial, and organizational model they function on, at least, are descendants of the very mills we were sitting in. That said, I’m not sure we quite teased out the difference between the best model to create a product (or a good product), where we’d each like to work, vs what might be the best solution for a country’s (or a global) economy.

And finally, a visit to Derby itself, and its industrial museum, housed in what is grandly described as the world’s first factory, Derby’s Silk Mill. This was fascinating in two ways – the collection, exhibits and archive, and it’s search for a new role in the centre of the city with all the potential impact spaces such as this can play in the cultural, educational, and commercial life of a city.

Having had it’s funding recently brutally cut to an absolute bare minimum – lights and heating only, a skeleton staff – and consequently closed to the public, it is now in a desperate search for a new raison d’etre, a new use, a new business plan. The building is not just historic, but positioned right in the center of the city, and is a lovely space. The remaining staff (4, if I counted correctly), are trying to figure out a way to keep this heritage of manufacturing alive, while incorporating new models in the old space: of making, workshops, local knowledge, creative industries, small companies, balancing the public sector, the public good, the local community, and commercial interests in a single place. Potentially unfettered by the need to be a museum, but keen to keep some of the exhibits in some form, they aren’t scared to radically rethink their role within the urban context within which they exist. Good luck to them, and to Derby.

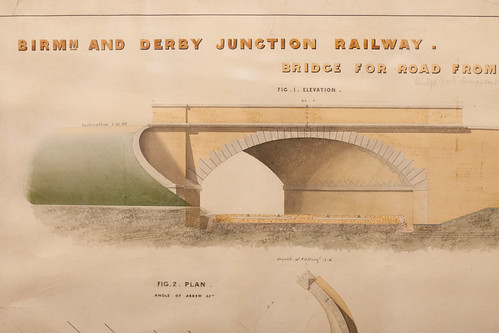

Geeking out at the collection itself, though, served it’s own purpose. Ranging from huge Rolls Royce aircraft engines to both scale and full-size models of the classic IntercityAPT (again), old railway signage, and an amazing archive of prints, it was a reminder how many of the things we’re working on in 2011 have been tacked a million times before, and a reminder of the levels of craft and attention to detail that were the norm, particularly in elements of transportation systems, the early days of the 20th century, and often lacking today. Sure, there are early experiments and missteps to learn from, too, but there are beautiful solutions that are all too often forgotten, languishing in dusty drawers of hand-drawn maps, silkscreened timetables, and cast-iron signage that we would do well to incorporate into our own work.

Thanks to Russell, Dan, and Toby for initiating and organizing the event, and everybody there for making this atypical excursion into the countryside an enjoyable and stimulating one.

Comments are closed

Comments are currently closed on this entry.